Why Choose Silicone Rubber Buttons for Your Products?

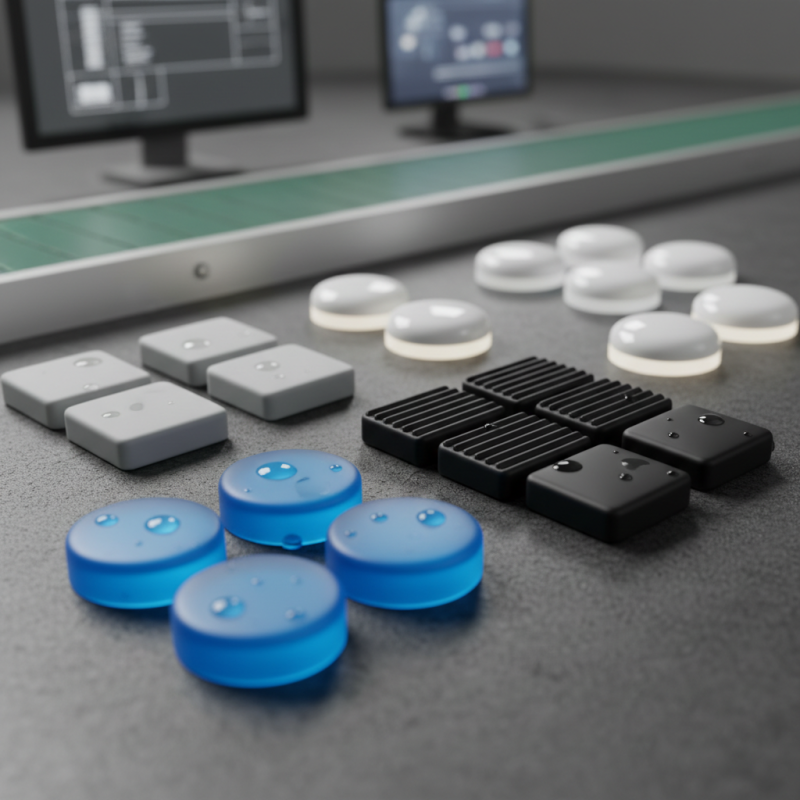

Silicone Rubber Buttons are increasingly popular in various industries. They offer durability and versatility that many products require. Their unique properties make them an excellent choice in consumer electronics, automotive applications, and medical devices.

The soft yet sturdy texture of Silicone Rubber Buttons enhances user experience. They provide excellent tactile feedback, making interactions seamless. Moreover, they resist water and dust, ensuring longevity. However, not all designs effectively utilize these buttons. Some may find it challenging to achieve the perfect touch sensation.

Choosing the right texture can be tricky. It is important to balance firmness with flexibility. Not every Silicone Rubber Button meets user expectations. Manufacturers must continually innovate to enhance these products. While they offer great benefits, there is always room for improvement.

Advantages of Silicone Rubber Buttons Over Other Materials

Silicone rubber buttons offer many advantages over traditional materials like plastic and metal. A recent industry report indicates that silicone buttons can withstand high temperatures and harsh environments, making them ideal for various applications. They remain functional in extreme heat, up to 200°C, and maintain elasticity in freezing conditions. This resilience can be critical for products used outdoors or in industrial settings.

In terms of design, silicone buttons allow for more flexibility in shapes and textures. They can be easily molded into intricate designs, enhancing the aesthetic appeal of a product. Reports suggest that 70% of consumers prefer products with a tactile feel, which silicone provides. However, the production of silicone buttons can sometimes lead to inconsistent quality, raising concerns for manufacturers focused on reliability.

Another notable advantage is their durability. Silicone rubber buttons resist wear more effectively than plastic ones. They don't crack or fade easily, ensuring a longer product lifespan. Yet, while their longevity is commendable, the initial cost can be higher than plastics. This high entry investment may deter some businesses. Balancing quality and cost is often a challenge in selecting materials.

Durability and Longevity: Why Silicone Stands the Test of Time

Silicone rubber buttons are popular in many products. Their durability is remarkable. These buttons withstand wear and tear better than other materials. They resist UV rays, moisture, and extreme temperatures. This resistance leads to longer product life. Consumers appreciate the quality touch of silicone. It feels good and lasts long.

Longevity is another key point. Silicone doesn’t crack easily. It also retains its flexibility over time. Many users notice that silicone buttons remain responsive even after years of usage. However, some may wonder about the environmental impact. Not all silicone is sustainable, which raises questions.

Choosing silicone can be a mixed decision. While its durability is proven, awareness of sustainability is crucial. Manufacturers are exploring eco-friendly alternatives. Striking a balance between quality and responsibility is challenging. In the end, understanding these factors is essential for smarter product design.

Durability Comparison of Silicone Rubber vs. Other Materials

Design Flexibility: Customization Options for Silicone Rubber Buttons

Silicone rubber buttons are increasingly popular in product design. One major reason is their design flexibility. Manufacturers can customize shapes, sizes, and colors to fit specific needs. This means a silicone button can seamlessly blend into the overall product aesthetic. Creating a unique look is now easier than ever.

Customization options can be extensive. For instance, different textures can enhance grip or improve user interaction. Companies often overlook this aspect, thinking simply of color and shape. But texture can impact functionality dramatically. Moreover, the tactile response of a button matters greatly to user experience. Users often remember how a button feels.

However, challenges can arise during the customization process. Designers may find that their initial ideas do not translate well into the silicone medium. There might be limitations in producing intricate designs. It's important to regularly test prototypes to ensure they meet expectations. Iteration is key in achieving the desired outcome. Embracing these challenges can lead to innovative solutions.

User Experience: Enhancing Functionality and Comfort with Silicone

Silicone rubber buttons can significantly enhance user experience in various products. Their tactile feel offers comfort during use. This material adapts well to different temperatures, making it suitable for diverse environments. Users often prefer a soft, yielding touch over hard plastics. The gentle pressure gives feedback, making usage intuitive.

Moreover, silicone buttons can be molded into various shapes and sizes. This versatility allows for unique designs that merge functionality with aesthetics. However, not all designs are practical. Some may feel too soft or too squishy, leading to user frustration. It’s essential to find a balance between softness for comfort and firmness for effectiveness.

Incorporating silicone buttons can also improve device ergonomics. They enhance grip, especially in handheld devices. Users might find buttons placed at awkward angles challenging. This concern can discourage use. Therefore, thoughtful placement and design are crucial. Often, this requires revisiting prototypes to achieve the best user experience.

Environmental Considerations: Eco-Friendly Aspects of Silicone Rubber

Silicone rubber buttons are gaining popularity due to their eco-friendly properties. Unlike many plastics, silicone is a sustainable material. It is durable and can withstand extreme conditions, reducing the need for replacements. According to a 2021 report by the Environmental Protection Agency, silicone products can last up to 50 years, minimizing waste in landfills.

The environmental impact of silicone rubber is notably lower than that of conventional materials. Unlike PVC or polyurethane, silicone does not release harmful substances when produced or disposed of. This makes it an excellent choice for manufacturers who aim for sustainability. In fact, studies show that switching to silicone can reduce carbon footprints by up to 20%.

Tip: Consider sourcing silicone from suppliers who follow environmentally friendly practices. Always ask about the recycling options available for silicone products.

The production process of silicone has its flaws, though. It requires energy, and if not managed carefully, it could lead to emissions. It's crucial to find a balance between benefits and drawbacks. By opting for high-quality silicone, businesses can enhance longevity while being mindful of the environment.

Tip: Regular assessments of manufacturing processes can help reduce energy waste. This not only saves costs but also contributes to a greener planet.