Why Choose a Laboratory Sample Pulverizer for Your Research Needs?

In the dynamic realm of research, the choice of tools can significantly impact outcomes. A laboratory sample pulverizer stands out as essential for precise analysis. Dr. Emily Carter, a renowned expert in material science, emphasizes, "A reliable pulverizer ensures uniformity in sample preparation." This statement highlights the crucial role of these devices.

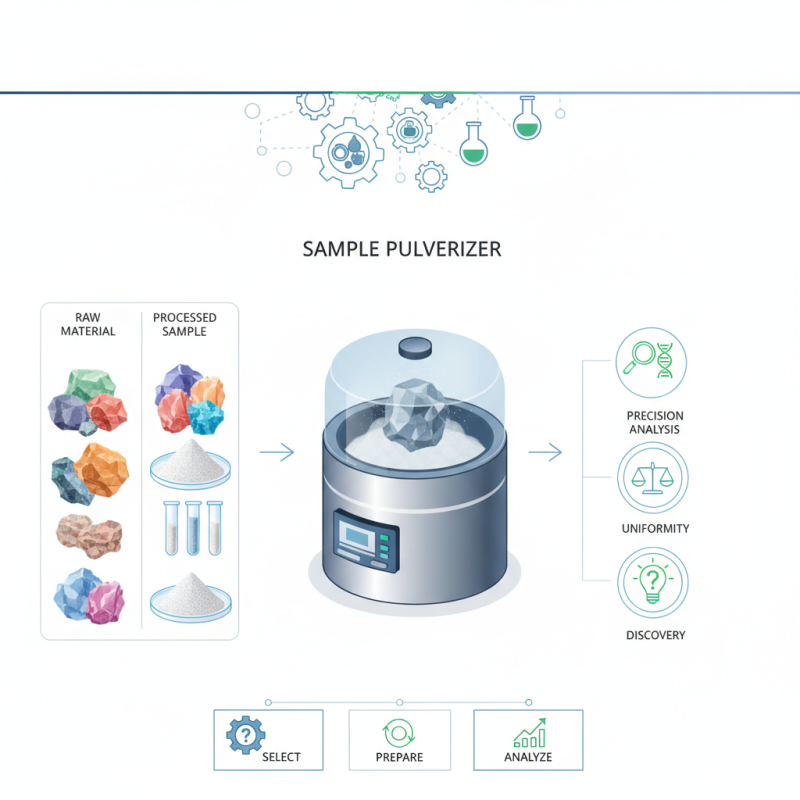

laboratory sample pulverizers transform raw materials into fine powders. This process enhances the accuracy of experiments. Researchers must consider various factors when selecting a pulverizer. Options can vary widely in capacity and specifications. The wrong choice may lead to inconsistent results, hampering research integrity.

Investing in a high-quality laboratory sample pulverizer fosters better insights and discoveries. However, not all models are created equal. It's vital to assess specific needs carefully. Research often involves trial and error, sometimes yielding imperfect results. Finding the right pulverizer is a journey of reflection and learning.

Benefits of Using a Laboratory Sample Pulverizer in Research

Laboratory sample pulverizers are essential tools in research. They provide efficiency in preparing samples for analysis. With the right pulverizer, researchers can achieve uniform particle sizes. This uniformity is crucial for reliable and reproducible results. Fine powders allow for better chemical reactions and enhanced analytical clarity.

Using a pulverizer can also save time in the lab. Instead of manual grinding, which can be inconsistent, these machines streamline the process. However, it’s important to choose the right settings. Incorrect settings may lead to heat generation, affecting sample integrity. Adjusting the speed and time can be a trial-and-error process. Such lessons help refine the use of the equipment.

Moreover, laboratory sample pulverizers facilitate multitasking. While one sample is being processed, researchers can focus on other tasks. Yet, oversight is key. Leaving a machine unattended can lead to unanticipated outcomes. This balance between productivity and caution is essential in research. In the quest for precision, refinement in technique is always necessary.

Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers come in various types, each serving unique purposes in research. These devices can significantly enhance the analysis of materials. The most common types are knife mills, ball mills, and disc mills. Knife mills are ideal for soft, fibrous materials. They use sharp blades to cut samples down to size. Ball mills, on the other hand, grind materials into fine powders. They are useful for mineral processing and material characterization. Disc mills excel in providing uniform particle sizes, which is vital for precise scientific results.

Understanding the right application for each type is crucial. For instance, a ball mill can efficiently grind hard minerals, but may not be the best choice for brittle materials. A study by the American Society for Testing and Materials revealed that using the appropriate pulverizer can impact test results by up to 30%. Hence, researchers must carefully select their pulverizer based on the sample's characteristics.

Tips: Always consider the material’s hardness and texture. If uncertain, consult industry guidelines or peer-reviewed studies. Take the time to reflect on your choice. Sometimes, the optimal pulverizer may not be the most expensive one. Experience plays a key role, so do not hesitate to experiment with different models to find the best fit for your research.

Key Features to Consider When Selecting a Pulverizer

When selecting a laboratory sample pulverizer, several key features should be considered. The particle size reduction is crucial. A well-functioning pulverizer can achieve a particle size of 100 microns or smaller. This is essential for accurate analysis in fields such as materials science and pharmaceuticals. According to a report by the American Chemical Society, particle size significantly affects the reactivity and properties of materials.

Another important feature is the material construction. Stainless steel and ceramic materials are common for high-quality pulverizers. These materials resist wear and contamination, ensuring consistent results. The durability of the pulverizer is vital since it directly impacts research outcomes. A device that fails frequently can lead to disrupted workflows and experimental delays.

Easy maintenance and user-friendliness are also worth considering. A pulverizer that is difficult to clean may introduce variability in future samples. Studies indicate that contamination during sample preparation compromises test integrity. Additionally, noise levels during operation can affect the work environment. Some pulverizers can be excessively loud, which is distracting in a busy lab setting. These factors should be weighed carefully when making a decision.

Why Choose a Laboratory Sample Pulverizer for Your Research Needs? - Key Features to Consider When Selecting a Pulverizer

| Feature | Description | Importance |

|---|---|---|

| Material Compatibility | Ability to grind various materials including metals, minerals, and plastics. | Ensures the pulverizer can be used for different research applications. |

| Size Reduction Ratio | The ratio of the original particle size to the final size after pulverization. | Higher ratios enable better results in analysis and testing. |

| Ease of Cleaning | Quick and easy to disassemble and clean. | Reduces cross-contamination and saves time between tests. |

| Power Consumption | Efficiency of the pulverizer in terms of energy usage. | Lower power consumption can result in reduced operating costs. |

| Noise Level | Amount of noise produced during operation. | Lower noise levels are preferable for laboratory environments. |

| Sample Capacity | Maximum amount of sample material that can be processed at once. | Larger capacity can increase throughput for high-demand applications. |

| Safety Features | Incorporation of safety mechanisms to protect users. | Essential for maintaining a safe working environment. |

How to Maintain and Care for Your Laboratory Pulverizer

Maintaining a laboratory sample pulverizer is essential for optimal performance. Regular cleaning helps prevent contamination. After each use, disassemble the pulverizer. Clean the parts with a soft brush or cloth. Some researchers overlook this step, leading to inaccuracies in future samples. Don't ignore this.

Check the blades frequently for wear. Dull blades can affect the sample quality. Replace them as needed. Many users delay blade replacements, thinking it’s fine. This can lead to poor results and wasted materials. Stay vigilant about maintenance schedules.

Calibration is also crucial. Ensure your pulverizer is calibrated according to the manufacturer's guidelines. A miscalibrated instrument can produce inconsistent results. This is often overlooked in busy labs. Take the time to check calibration regularly. By prioritizing these maintenance tasks, you can enhance the reliability of your research outcomes.

Comparative Advantages Over Traditional Grinding Methods

Lab sample pulverizers offer benefits that traditional grinding methods often lack. They provide consistent particle size, which is crucial for accurate research results. With advanced technology, these pulverizers can efficiently process hard materials, unlike conventional approaches that struggle with tough samples.

Another notable advantage is time efficiency. Traditional grinding can be slow and labor-intensive. In contrast, pulverizers can significantly reduce preparation time, allowing researchers to focus on analysis. The ease of cleaning these machines is another factor. Unlike traditional methods, where residue can linger, modern designs facilitate quick transitions between samples.

However, there are challenges to consider. Not all pulverizers are designed for every type of sample. Selecting the right equipment requires careful thought and research. There’s also the initial cost. While long-term benefits exist, upfront investment can be daunting for some labs. Each decision must weigh these factors to align with research goals.